To lay the foundation for a successful exploration of Lean Culture based in key principles, we would expore such topics as : What is Culture?, The Role of Leadership in Building a Lean Culture, How Kata Can Help You Build a Lean Culture, The 5 Pillars of a Sustainable Lean Culture, Why Standard Work is the Backbone of Lean Culture, Visual Management: Making Problems Visible in a Lean Culture, amongst others

These short but insightful snippets/titles on Lean Culture are inspired by “Creating a Lean Culture” by David Mann, and “Toyota Kata” by Mike Rother, plus other Lean principles.

These short titles and outlines focused on Lean Culture are designed to provide short, actionable insights and thought-provoking narratives for readers interested in Lean Culture.

Each snippet will be published in series

Look out for new snippets on the blog/insights page

Introduction

Simply put, “Culture is the sum total of all behaviours, relationships, comprehension, and interactions that fuel overall alignment via collective thoughts, words, and actions” (The Lean Handbook Anthony Manos, Chad Vincent, editors).

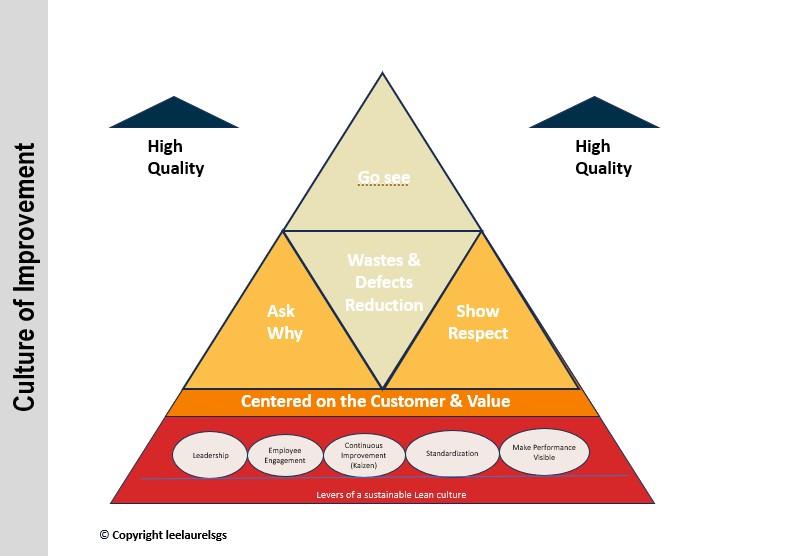

A sustainable Lean culture relies on several key pillars: Continuous Improvement, Respect for People, Value-Driven Processes, and Leadership Commitment. These pillars work together to create a culture where waste is minimized, employee engagement is high, and long-term sustainability is achieved. This pillar focuses on empowering employees, involving them in decision-making, and creating a supportive work environment where their ideas and expertise are valued.

Dombrowski, T. Mielke, in the publication, Lean Leadership – 15 Rules for a Sustainable Lean Implementation, publication (2014), emphasised the importance of Lean Leadership and suggested that Lean leadership could be the missing link between toolbox lean and a sustainable continuously improving organization.

He further explained that a common approach can be explained by using the 4P Model that consists of 4 levels that are all necessary for sustainable lean implementation. The levels are philosophy (long-term thinking), process (eliminate waste), people and partner (respect, challenge and grow them) and problem solving (CIP and learning).

Our aim, in Leelaurels is to have IMPROVEMENT as a key aspect of the organisational culture, creating a learning organisation that continuously grows.

A Culture of Improvement is not just about tools and processes—it’s about mindset and behavior. Here’s how its core principles drive meaningful change:

Ask Why:

The foundation of improvement lies in curiosity. By repeatedly asking “Why?” (the 5 Whys technique), teams can dig deeper to uncover the root cause of problems rather than just addressing symptoms. This approach fosters critical thinking and problem-solving.

Go See (Gemba):

Improvement happens where the work is done. Leaders and teams must go to the Gemba—the actual place where value is created—to observe processes, engage with employees, and gather firsthand insights. This builds empathy and ensures decisions are grounded in reality

Show Respect:

A Culture of Improvement values every team member’s contribution. By showing respect for employees’ knowledge and experience, organizations empower them to take ownership of processes and suggest improvements.

Waste & Defects Reduction:

Waste (muda) and defects are enemies of efficiency. By identifying and eliminating the 8 Wastes of Lean (e.g., overproduction, waiting, unnecessary motion), organizations can streamline operations and improve quality.

Centered on Customer & Value:

Every improvement must align with delivering value to the customer. By understanding customer needs and focusing on what truly matters, organizations can prioritize efforts that drive satisfaction and loyalty.

A Culture of Improvement, guided by Lean principles and reinforced through Kaizen Walkthroughs, creates a powerful engine for growth. By asking why, going to the Gemba, and showing respect, organizations can uncover hidden opportunities. Lean’s focus on identifying, eliminating, and sustaining improvements ensures that changes are both impactful and lasting. Meanwhile, Kaizen provides the practical tools and methods to turn ideas into action.

The journey to improvement is ongoing, but with the right mindset, principles, and tools, organizations can achieve remarkable results. Start small, stay consistent, and always keep the customer at the center of everything you do.

Remember, improvement isn’t a one-time event—it’s a journey. Start small, stay consistent, and watch your organization transform.

Need help implementing Lean? Contact/Get in Touch with our Certified Lean practitioners. (info@leelaurelgs.com, +2348062905881, +234817409633)

Contact Us

leelaurelsGS

Tel +234 8177409633, +2348062905881,

email – info@leelaurelsgs.com

website – leelaurelsgs.com